Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Equipment List and Capabilities

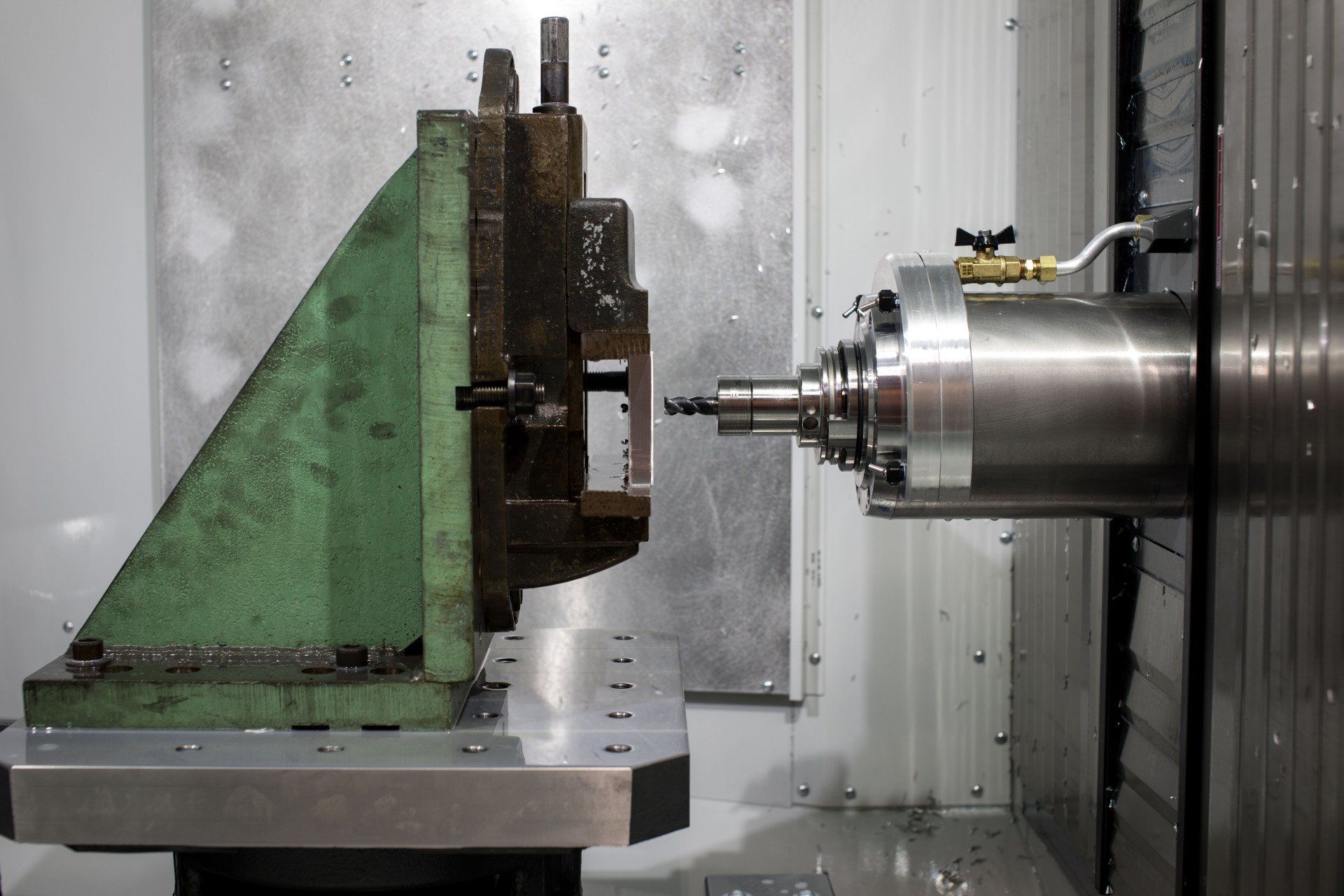

CNC HORIZONTAL BORING & MILLING

When your application requires precise horizontal boring and milling machines, our horizontal boring machines give your company the accuracy and speed to complete more jobs than ever before.

CNC HORIZONTAL MACHINING CENTERS

CNC machining is a subtractive manufacturing process that uses rotating computer-controlled cutting tools like drills, end mills, and turning tools to remove material from a solid block of material, thereby shaping the part.

CNC VERTICAL BORING / TURNING

Vertical boring mills are mainly used for turning, facing, or boring large cylindrical workpieces and work much like a horizontal lathe stood on one end. Two vertical uprights are mounted to the back of the diameter of the table, which bolsters a cross rail. The cross rail can be maneuvered up and down on the support columns in order to accommodate various workpieces.

CNC HORIZONTAL TURNING

Machining processes make up a critical part of manufacturing. CNC turning is widely appreciated for its versatility, making it one of the most commonly used CNC processes.

Horizontal lathes do not have a fixed spindle but use a variety of heads mounted to a horizontal arbor. These machines accommodate a wider variety of shapes and sizes and gravity works to keeping the workpiece clean during machining. Most horizontal lathes have the capacity to incorporate automatic bar-stock feeders.

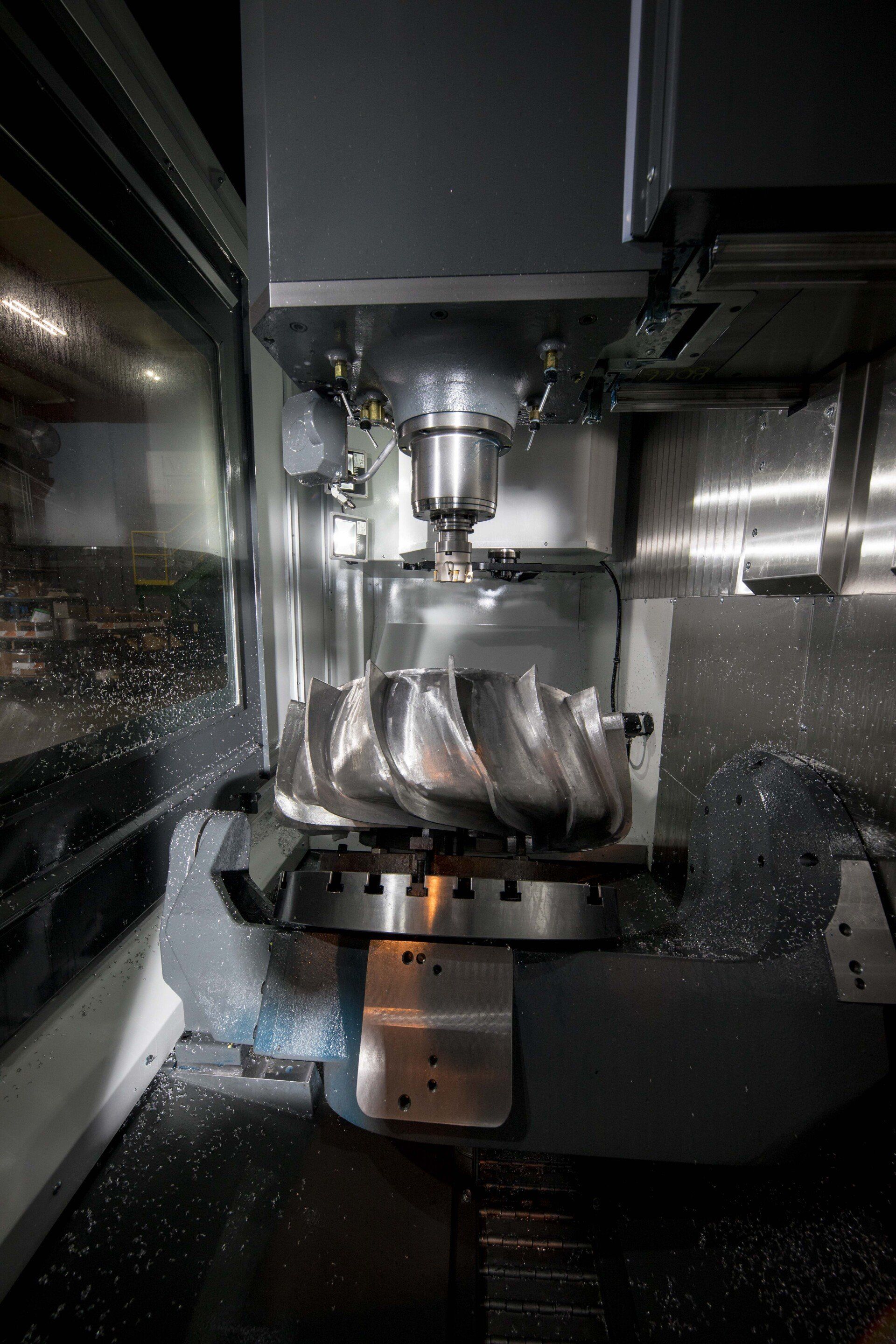

Description Title

5-axis machining is the most advanced form of metalworking and makes the impossible possible. It allows us to easily machine unusually shaped, custom, or unique parts while tackling improvements in processing efficiency and process flow procedures. 5-axis machining technology is known for its high efficiency, high precision capabilities, and its ability to produce incredible features on parts that are otherwise unattainable.

Our 5-axis capabilities complement our plant's ability to take on any manufacturing project and allows us to use advanced techniques to provide customers with the parts they need. Using our vast machining knowledge, we utilize our 5-axis machine to manufacture complex features on machined parts, castings, weldments, and bar/plate stock of virtually any material for an array of applications. This machine helps us bring the customers part to life, whether it’s in the aerospace, military, medical, industrial, civil, or private sector.